What Are Three Types Of Service Operations

Operations management for services has the functional responsibleness for producing the services of an arrangement and providing them direct to its customers.[ane] : 6–7 It specifically deals with decisions required past operations managers for simultaneous production and consumption of an intangible production. These decisions concern the procedure, people, data and the system that produces and delivers the service. It differs from operations direction in general, since the processes of service organizations differ from those of manufacturing organizations.[2] : 2–7

In a post-industrial economic system, service firms provide about of the GDP and employment. As a result, management of service operations within these service firms is essential for the economy.[iii]

The services sector treats services every bit intangible products, service every bit a client experience and service equally a packet of facilitating appurtenances and services. Meaning aspects of service every bit a product are a basis for guiding decisions made by service operations managers.[four] The extent and diverseness of services industries in which operations managers make decisions provides the context for determination making.

The vi types of decisions made past operations managers in service organizations are: procedure, quality direction, capacity & scheduling, inventory, service supply chain and information technology.[5]

Definition of services [edit]

At that place accept been many different definitions of service. Russell and Taylor (2011) state that ane of the well-nigh pervasive, and earliest definitions is "services are intangible products".[6] According to this definition, service is something that cannot be manufactured. Information technology tin exist added subsequently manufacturing (e.g. product repair) or information technology tin stand up lonely as a service (due east.g. dentistry) delivered directly to the client. This definition has been expanded to include such ideas as "service is a customer experience."[7] : 7–8, 162–192 [8] In this case the client is brought into the definition as the experience the customer receives while "consuming" the service.

Service is a customer experience

A third definition of service concerns the perceived service as consisting of physical facilitating goods, explicit service and implicit service.[6] In this case the facilitating appurtenances are the buildings and inventory used to provide the service. For instance, in a restaurant the facilitating goods are the building and the food. The explicit service is what is perceived every bit the observable part of the service (the sights, sounds and wait of the service). In a restaurant the explicit service is the time spent waiting for service, the appearance of the facility and the employees, and the ambience of sounds and light and the decor. The implicit service is the feeling of condom, psychological well-being and happiness associated with the service.

Comparing of manufacturing and services [edit]

Co-ordinate to Fitzsimmons, Fitzsimmons and Bordoloi (2014) differences between manufactured goods and services are as follows:[4] : fourteen–xviii

- Simultaneous production and consumption. High contact services (e.k. haircuts) must be produced in the presence of the customer, since they are consumed equally produced. As a result, services cannot be produced in one location and transported to another, like goods. Service operations are therefore highly dispersed geographically shut to the customers. Furthermore, simultaneous production and consumption allows the possibility of self-service involving the client at the point of consumption (east.g. gas stations). Merely low-contact services produced in the "backroom" (e.k., check clearing) can be provided away from the client.

- Perishable. Since services are perishable, they cannot be stored for later on utilise. In manufacturing companies, inventory tin be used to buffer supply and demand. Since buffering is not possible in services, highly variable demand must be met past operations or need modified to run across supply.

- Ownership. In manufacturing, ownership is transferred to the client. Ownership is not transferred for service. Every bit a result, services cannot exist owned or resold.

- Tangibility. A service is intangible making it difficult for a client to evaluate the service in advance. In the case of a skilful, customers can see it and evaluate it. Assurance of quality service is often done by licensing, authorities regulation, and branding to assure customers they will receive a quality service.

These four comparisons bespeak how management of service operations are quite different from manufacturing regarding such bug equally capacity requirements (highly variable), quality balls (difficult to quantify), location of facilities (dispersed), and interaction with the customer during commitment of the service (production and process pattern).

Service industries [edit]

Industries have been defined past economists every bit consisting of iv parts: Agriculture, Mining and Construction, Manufacturing, and Service.[9] Services have existed for centuries. Early on service was associated with servants. Servants were hired to do tasks that the wealthy did not want to do for themselves (e.m. cleaning the business firm, cooking, and washing apparel). Later, services became more than organized and were provided to the general public.

In 1900 the U.S. service industry (e.k., consisting of banks, professional services, schools and general stores) was fragmented, except for the railroads and communications. Services were largely local in nature and owned by entrepreneurs and families. The U.S. in 1900 had 31% employment in services, 31% in manufacturing and 38% in agriculture.[10]

Services accept now evolved to get the dominant form of employment in industrialized economies. Much of the world has progressed, or is progressing, from agronomical to industrial and at present post-industrial economies.[3] The U.South. Bureau of Labor Statistics provides a table of the employment of the 151 million people past manufacture in the U.S. for 2014.

| Industry | % employment |

|---|---|

| Agriculture and Mining | 2 |

| Structure | 5 |

| Manufacturing | 10 |

| Federal Government | 2 |

| Land Governments | thirteen |

| Leisure & Hospitality | 9 |

| Health Care and Social | 10 |

| Pedagogy Individual | 2 |

| Professional and Business | eleven |

| Financial Services | half-dozen |

| Information Services | 2 |

| Transportation & Utilities | 3 |

| Retail and Wholesale | 14 |

| Other services | 4 |

| Cocky Employed | vii |

| Totals | 100 |

Source:[9]

The table shows that service industries now constitute 83% of employment in the U.South., while agronomics, mining, structure and manufacturing are only 17% of the total employment. Service industries are very diversified ranging from those that are highly capital intensive (east.g. banks, utilities, airlines, and hospitals) to those that are highly people intensive (east.thousand. retail, wholesale, and professional person services). In capital intensive services the focus is more on engineering and automation, while in people intensive services the focus is more than on managing service employees that deliver the service.[6]

Service and manufacturing industries are highly interrelated. Manufacturing provides tangible facilitating goods needed to provide services; and services such as banking, accounting and information systems provide important service inputs to manufacturing. Manufacturing companies have an opportunity to provide more than services along with their products. This can be an of import bespeak of product differentiation, leading to increased sales and profitability for manufacturers.[2] : 2–7

While the focus is often on service industries, in that location is an opportunity to apply service principles to internal services in an organization, peculiarly by focusing on internal customers. Internal services such every bit payroll, bookkeeping, legal, information systems or human resources often accept not identified their internal customers, nor practice they empathise their customer needs. Service ideas ranging from procedure design, to lean systems, quality management, capacity and scheduling take been widely applied to internal services.[11] [seven] : 30–32

Service design [edit]

Service blueprint begins with a business strategy and service strategy. The business organisation strategy defines what business the house is in, for case, the Walt Disney Company defines its concern strategy "every bit making people happy." A business strategy likewise defines the target market place, competitors, financial goals, new products, how the company competes, and peradventure some aspects of operations.

Following from the business strategy is the service concept.[7] : 47–50 It must provide the rationale for why the customer should purchase the service offered. Information technology defines what the customer is receiving and what the service organization is providing. The service concept includes:

- Organizing Thought. The vision and essence of the service.

- Service Provided. The procedure and results designed by the provider.

- Service Received. The client feel and outcomes expected.

Managers tin use the service concept to create organizational alignment and develop new services. Information technology provides a ways for describing the service business from an operations bespeak of view.

After defining the service concept, operations can proceed to define the service-production bundle (or service package) for the organization. Information technology consists of v parts: service facility, facilitating appurtenances, data, explicit service and implicit services.[4] It is important to carefully define each of these elements so that operations can subsequently design and manage a service functioning. The service-product bundle must come offset before operations decisions.

An example of service-production bundle characteristics follows:[4] : eighteen–19

- Service Facility: Accessible past public transportation, sufficient parking, interior decorating, compages, facility layout and traffic period

- Facilitating goods: sufficient inventory, quality and selection

- Information: Is it accurate, up-to-date, timely, and useful to the customer and service providers

- Explicit service: waiting time, grooming and advent of personnel, and consistency

- Implicit service: Sense of well-being, privacy and security, atmosphere, attitude of service providers.

One time the service package is specified, operations is prepare to make decisions concerning the process, quality, capacity, inventory, supply concatenation and data systems. These are the six decision responsibilities of service operations. Other decision responsibilities such as market place choice, product positioning, pricing, advertisement and channels belong to the marketing function. Finance takes care of fiscal reporting, investments, capitalization, and profitability.

Operations decisions [edit]

Process decisions [edit]

Process decisions include the physical processes and the people that deliver the services to the customer. A service process consists of all the routines, tasks and steps that are used to deliver service to customers forth with the jobs and preparation for service employees. There are many ways to organize a process to provide client service in an effective and efficient manner to deliver the service-production package. Several ideas have been advanced on how to design a service process.[12] : 173–243, 401–431

Customer contact [edit]

Design of a service organization must consider the caste of customer contact. The importance of customer contact was first noted by Chase and Tansik (1983).[13] They argued that high customer contact processes should be designed and managed differently from low-contact processes. High-contact processes have the customer in the arrangement while providing the service. This can lead to difficulties in standardizing the service or inefficiencies when the client makes demands or expects unique services. On the other hand, loftier-contact also provides the possibility of self-service where customers provide part of the service themselves (eastward.g. filing your own gas tank, or packing your own groceries). Depression-contact services are performed away from the customer in what is oft chosen "the back room." In this example, the service process can be more standardized and efficient (eastward.g. cheque clearing in a banking concern, filling orders in a warehouse) since the customer is not in the system to request preferences, customization or changes. Low-contact services tin can exist managed more than like manufacturing, high-contact services cannot.

Production-line arroyo [edit]

McDonald's uses the production-line approach to service

In 1972 Levitt introduced the "production-line approach to service".[14] He argued that service processes could be made more than efficient past standardizing them and automating them similar manufacturing. He gave the example of McDonald'southward that has standardized both the services at the front counter and the backroom for producing the nutrient. They take limited the menu, simplified the jobs, trained the managers (at "Hamburger U"), automatic product and instituted standards for courtesy, cleanliness, speed and quality. As a consequence, McDonald's has become a model for other service processes which have been designed for loftier efficiency, not simply in fast nutrient, but in many other services. At the aforementioned time, it leaves open the option for more customized and flexible services for customers who are willing to pay more for "better" or more personalized service. While these services are less efficient, they cater more to unique client's needs.

Service process matrices [edit]

Many unlike service procedure matrices have been proposed for explaining the relationship between service products that are selected and corresponding processes.[7] : 193–225 I of these is shown below.

The Service Delivery System Matrix[fifteen] past Collier and Meyer (1998) illustrates the diverse types of routings used for service procedure depending on the corporeality of customization and client involvement in the procedure. With high levels of customization and customer interest, there are many pathways and jumbled flows for service. As a result, the service delivery of Customer-Routed services is less efficient than Co-routed or Provider-Routed processes that take less customization and less customer interest. Process that should be used for each combination of customization and client involvement are shown on the diagonal of this matrix.

Self-service [edit]

Cocky-service is in wide use. For example, in the 1960s gas station attendants came out and pumped your gas, cleaned your windshield and even checked your oil. Fast food is famous for self-service, since customers have been trained to society their own food, pay immediately, find a table, and clean up the trash. ATM's accept replaced many traditional tellers and online banking provides fifty-fifty more cocky-service.

When self-service is accepted past the customer, it can reduce costs and even provide better service in the customer'south eyes—faster service with less hassle.[12] : 173–243, 401–431 Self-service falls in the provider-routed or co-routed part of the Service commitment matrix. Services that were previously customer-routed have been moved down the diagonal to be more efficient and accepted by customers.

Service Blueprint The service blueprint is a manner to describe the flow of a customer through a service operation from the start to the finish, along with the deportment provided past the service providers both in interaction with the customer and in the "back room" out of sight of the customer. For example, if a customer wishes to purchase a suit, the service blueprint starts with entry to the shop, next the client is greeted past a sales representative, the customer and then provides information on his/her needs, the sales representative searches for appropriate suits, ane or more than suits are selected and tried-on for a plumbing equipment, a conform is selected and so alterations are done (which take identify away from the client), the customer pays for the adapt and returns later to pick it up. A pattern flowchart shows every pace in the process and can be used to illustrate the process and ameliorate information technology.[xvi]

Lean thinking [edit]

If lean thinking is applied, the time taken for each step in a service blueprint flowchart can be recorded, or a separate value-stream map can be constructed. Then the process can exist analyzed for time reductions to reduce waiting and not-value added steps.[11] Changes are made to reduce fourth dimension and waste in the procedure. Waste material is anything that does not add together value to the process including waiting time in line, possibility of more than self-service, client hassle, and defects in service. But, lean thinking also requires attention to the customer and the people providing the service. Information technology is of import to apply important principles such as completely solve the client'due south problem, don't waste matter time and provide exactly what the customer requires.

Leite and Vieira (2015) state that service managers must realize that the customer will be happy if the service provided meets or exceeds expectations. Likewise the interaction between the customer and the people providing the service is essential to reach satisfied customers. Employee involvement is often emphasized equally part of lean thinking to achieve loftier levels of delivery by service employees.[17]

Queuing [edit]

Mail function queue. Operations management studies both manufacturing and services.

Queuing is an analytic method for determining waiting time when customers must look in line to go service. The length of the queue and waiting time can be calculated based on the arrival rate, service rate, number of servers and type of lines. There are many formulas for diverse types of queuing theory problems.[18] The formulas generally predict that the average service time must be significantly less than the average time betwixt arrivals when there is randomness in arrivals and/or service time. The reason for this is that a long line volition build up when randomness of arrivals occurs faster than the boilerplate and service times are longer than the average. If the distributions of inflow times and service times are known, formulas are bachelor for calculating the exact waiting times and line lengths for many unlike queuing configurations of servers, types of lines, server distributions and arrival distributions.

Service-profit chain [edit]

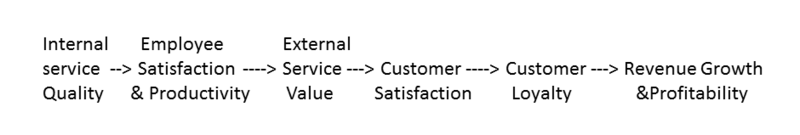

Heskett, Sasser and Schlensinger (1997) proposed the service-turn a profit chain as a way to design service processes. The service-profit chain links various aspects and tasks required to evangelize superior service and profits. It starts with a loftier level of internal quality leading to employee satisfaction and productivity to evangelize superior external customer service leading to customer satisfaction, customer loyalty and finally high revenues and profits.[nineteen]

A description of the service-profit chain

Every link in this chain is of import and the linkage between the service providers and the customer is essential in service operations. The service managing director should not break any of the links in gild to receive the results of high probability and growth.

Quality direction [edit]

SERVQUAL measurement [edit]

Using the customer feel approach, a questionnaire called SERVQUAL has been developed to measure the customer's perception of the service.[20] The dimensions of SERVQUAL are designed to measure the customer experience in both explicit and implicit measures. The dimensions are:

- Tangible: Cleanliness, advent of facilities and employees

- Reliability: Accurate, undecayed and consistent services without errors

- Responsiveness: Promptly assist customers in a timely manner

- Assurance: Conveying knowledge, trust and confidence

- Empathy: Caring, approach-ability and relating to customers

A argue well-nigh SERVQUAL has ensued well-nigh whether client service should exist measured in absolute terms or relative to expectations.[21] Some fence that if high levels on all SERVQUAL dimensions are provided and then the service is loftier quality. Others debate that ultimately the service result is judged past the client relative to the customer'southward expectations and not by the service provider. If customer expectations are low, even depression levels on SERVQUAL dimensions provides high quality.

Quality direction approaches [edit]

Quality management practices for services accept much in common with manufacturing, despite the fact that the product is intangible. The following approaches are widely used for quality comeback in both manufacturing and services:

- The Baldrige Awards: A comprehensive framework for quality improvement in organizations[22]

- The West. Edwards Deming Direction Method: 14 Points for Management[23]

- Joseph Juran's Approach: Planning, Comeback and Control[24] [25]

- Six Sigma: DMAIC (Design, Measurement, Analysis, Comeback and Control)[26] [27]

These approaches have several things in mutual. They begin with defining and measuring the client'south needs (e.g. using SERVQUAL). Any service that does non meet a customer's demand is considered a defect. So these approaches seek to reduce defects through statistical methods, cause-and-outcome analysis, problem solving teams, and involvement of employees. They focus on improving the processes that underlie production of the service.[28]

In addition to intangibility, there are ii approaches about quality that are unique to service operations direction.

Service recovery [edit]

For manufactured products, quality problems are handled through warranties, returns and repair subsequently the product is delivered. In high contact services in that location is no time to set quality problems afterwards; they must be handled by service recovery as the service is delivered. For instance, if soup is spilled on the customer in a eating place, the waiter might apologize, offer to pay to have the suit cleaned and provide a costless meal. If a hotel room is not ready when promised, the staff could apologize, offering to shop the customer's luggage or provide an upgraded room. Service recovery is intended to gear up the problem on the spot and go even farther to offering the customer some grade of consolation and compensation. The objective is to make the customer satisfied with the situation, even though in that location was a service failure.[29] [thirty]

Service guarantee [edit]

A service guarantee is similar to a manufacturing guarantee, except the service product cannot exist returned. A service guarantee provides a specific budgetary reward for failure of service delivery. Some examples are:

- Your package will be delivered by the fourth dimension promised or you volition non pay.

- We will fix your auto or give you $100 if you must bring information technology back for repair.

- Customers that are non satisfied with their haircut, get the adjacent haircut free.

Service guarantees serve to clinch the customer of quality and they provide a way for the employees to know the price of service failure.[31] [32]

Chapters and scheduling [edit]

Forecasting [edit]

Forecasting demand is a prerequisite for managing capacity and scheduling. Forecasting demand oftentimes uses big information to predict customer beliefs. The information comes from scanners at retail locations or other service locations. In some cases traditional time serial methods are also used to predict trends and seasonality. Future demand is forecasted based on past demand patterns. Many of the same time-series and statistical methods for forecasting are used for manufacturing or service operations.[33] [34]

Capacity planning [edit]

Capacity planning is quite different betwixt manufacturing and services given that service cannot be stored or shipped to some other location.[ane] : 208–241 As a result, location of services is very dispersed to be near the customer. Customers are but willing to travel curt distances to receive most services. Exceptions are health care when the illness requires a specialist, airline transportation when the service is to move the customer, and other services where local expertise is not available. Aside from these exceptions, location assay depends on the "drawing power" based on the distance a customer is willing to travel to a service site relative to competitive offerings and locations. The drawing power of a site for a particular customer is high if the site is close past and provides the required service. High cartoon power is related to high sales and profits. This is very different from manufacturing locations which depend on the cost of building a factory plus the cost of transporting the goods to the customers. Manufacturing plants are located on the footing of low costs rather than high revenues and profits for services.

A second difference from manufacturing is planning for capacity utilization once a facility is built. Since the product cannot be stored in inventory and sold later, service capacity is perishable and must meet top demand at any point in time.[12] : 96–129 There are two ways to bargain with this problem. Beginning, direction can attempt to reduce acme demand and level it over time past the following actions.

- Higher prices during peak-demand times

- A reservation system to limit peak demand

- Advertising and promotion to shift peak need

Management tin can too use various methods to manage the supply of services including:

- Office-time labor

- Hiring and Layoff of Employees

- Using Overtime

- Subcontracting

While some of these same mechanisms are used in manufacturing, they are much more crucial in service operations.

Revenue management [edit]

Acquirement management is unique to services, since capacity is perishable. This applies to the airline industry. When the plane leaves the runway, empty seats generate no revenue, only the cost of the flying is almost the aforementioned. As a result, mathematical models have been formulated to allocate chapters at various prices and times as the flying is booked in advance. Initially, a sure number of seats are reserved for outset class, charabanc, premium coach and diverse other categories. Based on the elasticity of demand, seats prices are lowered at the final minute in order to fill empty seats and maximize the revenue of the flight.[35] Similar models accept also been adult for revenue management in hotels, where the capacity is likewise perishable.[36]

Scheduling [edit]

Scheduling has some differences between manufacturing and service. In manufacturing, jobs are scheduled through a factory to sequence them in the best order to run across due dates and reduce costs. In services, it is customers who are existence scheduled. As a result, waiting time becomes much more disquisitional. While manufacturing orders don't mind waiting in line or waiting in inventory, real customer's do mind. Some of the scheduling applications for services are: scheduling of patients to operating rooms in hospitals and scheduling students to classes. Many scheduling problems have been solved past using operations inquiry methods to optimize the schedule.[37]

Inventory [edit]

Inventory management and control is needed in service operations with facilitating goods. Almost every service uses some amount of facilitating goods. The presence of facilitating appurtenances is critical in retail and wholesale operations merely these operations don't industry anything, rather they distribute goods and provide service while doing it. One difference from manufacturing inventories is that services use simply finished goods, while manufacturing has finished goods, work-in-process and raw-materials inventories. As a consequence, manufacturing uses a Materials Requirements Planning Organization, while services do not. Services use Replenishment inventory command systems such every bit order-bespeak and periodic-review systems.[38]

Service supply bondage [edit]

Supply chains for service operations are critical to supply facilitating goods. A typical hospital supply chain is an example. A hospital volition apply many goods from suppliers to construct and furnish the edifice. During 24-hour interval-to-day operation of the hospital, inventories of supplies volition be held for the operating rooms and throughout the building. The pharmacy will hold drugs and the kitchen volition need supplies of food. The supply chain of facilitating appurtenances in hospitals is extensive.

Purchasing controls a large function of costs in retail and wholesale operations, approximately 75% of all costs are for purchased goods. Outside of retail and wholesale operations, facilitating goods are a much smaller part of total costs reaching a low of 10% for most professional services.[one] : 291–334 Both manufacturing and service organizations purchase appurtenances and must deal with outsourcing and offshoring, besides as, domestic products.

Service inputs are critical for manufacturing including capital from banks, free energy, data systems and human resources. Services are part of the manufacturing supply chain, just like the physical inputs of products from other manufacturing companies.

Both manufacturing and service operations can buy services from outside the organization. Internal business services such every bit accounting, legal, human resources, call centers, and information systems may exist outsourced in part or entirely. Some of these services tin also be purchased from offshore. Logistics services may be outsourced to Tertiary Political party Logistics (3PL) providers. These services include transportation, warehousing, order fulfillment, returns and tariffs.[7] : 31–32

Information technology [edit]

The Internet and data technology has dramatically changed the delivery of services. Some of the major changes are as follows:[4]

- Providing data and noesis straight to consumers. Before the Internet, consumers used a variety of sources for acquiring knowledge including libraries, telephone calls, universities and personal contacts. Now data tin be provided immediately as a service past searching the Internet.

- Providing service at a distance. Services such as call centers, banking, entertainment and legal services can exist provided over long distances, fifty-fifty internationally.

- Reservations can exist fabricated on the Cyberspace to reserve chapters more than easily than by calling alee for the reservation.

- Facilitating goods tin can be ordered straight by the Internet and delivered without traveling to a retail shop. The services provided includes browsing for merchandise, order entry, gild checking, payment, order confirmation, notification of delivery and return services.

- Internal information systems now provide an assortment of direction data to help managers brand better decisions.

Management science and operations research (MSOR) [edit]

Assay using MSOR methods has been extensive in services. Areas where they take been heavily applied are in inventory, capacity, scheduling, queuing and forecasting. With the advent of the Cyberspace, information systems, big data and analytics, there are many opportunities to make improvements in determination making for services. The analytic techniques include statistics, direction science[39] and operations research.[forty]

References [edit]

- ^ a b c Bozarth, Cecil and Handfield, Robert (2006). Introduction to Operations and Supply Chain Management. Upper Saddle River, Due north.J., Pearson. ISBN0-13-185804-1.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ a b Malhotra, Manoj K.; Krajewski, Lee J.; Ritzman, Larry P. (2013). Operations management : processes and supply chains (tenth ed.). Upper Saddle River, Northward.J.: Pearson. ISBN978-0-13-280739-five.

- ^ a b Bell, Daniel (1973). The coming of post-industrial guild; a venture in social forecasting. New York: Basic Books. ISBN978-0465012817.

- ^ a b c d east Fitzsimmons, James; Fitzsimmons, Mona; Bordoloi, Sanjeev (2014). Service Management: Operations, Strategy, Data Technology, 8th ed. New York: McGraw-Hill/Irwin. ISBN978-0-07-802407-eight.

- ^ Heizer, Jay; Render, Barry (2011). Operations Management, 10th ed.,. Upper Saddle River, N.J.: Prentice-Hall. pp. vii–8. ISBN978-0-13-611941-eight.

- ^ a b c Russell, Roberta; Taylor, Bernard (2011). Operations Management: Creating Value Along the Supply Chain, seventh ed . New York: John Wiley & Sons. p. 191. ISBN978-0-470-52590-half dozen.

- ^ a b c d e Johnston, Robert; Clark, Graham; Shulver, Michael (2012). Service Operations Management: Improving Service Delivery (Fourth ed.). London, England: Pearson. ISBN978-0-273-74048-3.

- ^ Meyer, Christopher; Schwager, Andre (February 2007). "Understanding Customer Feel". Harvard Business organisation Review.

- ^ a b Richard Henderson (2015). "Industry employment and output projections to 2024 : Monthly Labor Review". U.South. Bureau of Labor Statistics. Retrieved 2017-03-15 .

- ^ Fisk, Donald M. (2003-01-30). "American Labor in the Twentieth Century" (PDF). world wide web.bls.gov. U.S. Bureau of Labor Statistics. Retrieved 2017-03-xv .

- ^ a b Womack, J.P. and Jones, D.T. (2003). Lean Thinking. New York: Simon and Schuster. ISBN0-7432-4927-5.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ a b c Jacobs F. Robert and Hunt, Richard B. (2013). Operations and supply chain direction: The Core, tertiary ed. New York: McGraw-Loma/Irwin. ISBN978-0-07-352523-5.

- ^ Chase, Richard; Tansik, David (1983). "The Customer Contact Model for Organizational Design". Management Science. 29 (9): 1037–1050. doi:ten.1287/mnsc.29.9.1037.

- ^ Levitt, Theodore (1972). "The Production-Line Approach to Service". Harvard Business Review. 50 (iv): 41–52. OCLC 45573321.

- ^ Collier, David; Meyer, Susan (1998). "A Service Positioning Matrix". International Journal of Operations & Production Management. 18 (2): 1223–1244.

- ^ Shostack, Lynn (1984). "Designing Services that Deliver". Harvard Business organisation Review. 62 (1): 133–139.

- ^ Leite, Higor dos Reis; Vieira, Guilherme Ernani (September 2015). "Lean philosophy and its applications in the service industry: a review of the current knowledge". Production. 25 (iii): 529–541. doi:ten.1590/0103-6513.079012.

- ^ Gross, Donald (1974). Fundamentals of queueing theory. New York: Wiley. ISBN047132812X.

- ^ Schlesinger, James 50. Heskett ; W. Earl Sasser ; Leonard A. (1997). The service profit concatenation : how leading companies link profit and growth to loyalty, satisfaction, and value. New York, NY: Costless Press. ISBN978-0684832562.

- ^ Berry, Valarie A. Zeithaml, A. Parasuraman, Leonard L. (1990). Delivering quality service : balancing client perceptions and expectations. New York: Free Printing. ISBN9780029357019.

- ^ Nyeck, Simon; Morales, Miguel; Ladhari, Riadh; Pons, Frank (December 2002). "ten years of service quality measurement: reviewing the use of the SERVQUAL musical instrument". Journal of Economic science, Finance and Administrative Scientific discipline. vii (xiii).

- ^ "Malcolm Baldrige National Quality Award (MBNQA)". ASQ. Retrieved 2017-03-15 .

- ^ Deming, W. Edwards (1986). Out of the Crisis. MIT Press. ISBN9780262541152.

- ^ Juran, Joseph M. and DeFeo, Joseph A. (2010). Juran's Quality Handbook. New York: McGraw-Hill. ISBN978-0071629737.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ Juran, Joseph 1000. (2004). Architect of Quality: The Autobiography of Dr. Joseph M. Juran. New York: McGraw-Colina. ISBN978-0071589789.

- ^ Tennant, Geoff (2001). Vi Sigma: SPC and TQM in Manufacturing and Services. Grover Publishing, Ltc. ISBN9780566083747.

- ^ Breyfogle, Forrest W. III (1999). Implementing Six Sigma: Smarter Solutions Using Statistical Methods. John Wiley & Sons. ISBN9780471265726.

- ^ Harvey, J (1998). "Service quality: a tutorial". Periodical of Operations Management. 16 (5): 583–597. doi:ten.1016/S0272-6963(97)00026-0. ISSN 0272-6963.

- ^ Hart, Christopher; Heskett, James; Sasser, W. Earl Jr. (1990). "The Profitable Art of Service Recovery". Harvard Business Review. 68 (4): 148–56. PMID 10106796.

- ^ Maxham, James Chiliad. Iii (Oct 2001). "Service Recovery'due south Influence on Consumer Satisfaction, Word-of-Mouth and Purchase Intentions". Journal of Concern Research. 54: eleven–24. doi:ten.1016/S0148-2963(00)00114-four.

- ^ Hart, Christopher West.L. (July 1988). "The Power of Unconditional Service Guarantees". Harvard Concern Review: 54–62.

- ^ Baker, Tim; Collier, David (2005). "The Economic Payout Model for Service Guarantees". Conclusion Sciences. 36 (2): 197–220. doi:10.1111/j.1540-5414.2005.00071.x.

- ^ Armstrong, Scott, ed. (2001). Principles of Forecasting: A Handbook for Researchers and Practitioners. Norwell, Massachusetts: Kluwer Academic Publishers. ISBN978-0792374015.

- ^ Gilchrist, Warren (1976). Statistical Forecasting. London: John Wiley & Sons. ISBN978-0471994022.

- ^ Talluri, 1000; van Ryzin, One thousand (1999). "Revenue Management: Enquiry Overview and Prospects" (PDF). Transportation Science. 33: 233–256.

- ^ Cantankerous, R. (1997). Revenue Management: Hard-Core Tactics for Market Domination. New York: Broadway Books. ISBN978-0767900331.

- ^ Pinedo, Michael (2009). Planning and Scheduling in Manufacturing and Services (2nd ed.). Springer. ISBN978-1-4419-0909-1.

- ^ Muller, Max (2011). Essential of Inventory Management (2nd ed.). AMACOM. ISBN0814416551.

- ^ Thompson, Gerald E. (1982). Direction Scientific discipline: An Introduction to Mod Quantitative Analysis and Conclusion Making. New York: McGraw-Colina. ISBN978-0070643604.

- ^ Hiller, Frederick; Lieberman, Gerald (2014). Introduction to Operations Research (10th ed.). New York: McGraw-Hill. ISBN978-0077298340.

Further reading [edit]

- Hunt, Richard B.; Apte, Uday Yard. (March 2007). "A history of enquiry in service operations: What'southward the large idea?". Journal of Operations Management. 25 (two): 375–386. doi:10.1016/j.jom.2006.11.002.

- Sprague, Linda G. (March 2007). "Development of the field of operations management". Journal of Operations Direction. 25 (2): 219–238. doi:10.1016/j.jom.2007.01.001.

- Chase, Richard B. (Nov 1978). "Where Does the Customer Fit in a Service Operation?". Harvard Business organization Review. 56 (six).

What Are Three Types Of Service Operations,

Source: https://en.wikipedia.org/wiki/Operations_management_for_services

Posted by: bratcherwithile1984.blogspot.com

0 Response to "What Are Three Types Of Service Operations"

Post a Comment