How Does Southwestã¢â‚¬â„¢s Customer Service Affect Its Bottom Line

11.i Operations Management in Manufacturing

Learning Objectives

- Define operations management, and discuss the role of the operations manager in a manufacturing company.

- Describe the decisions made in planning the production process in a manufacturing company.

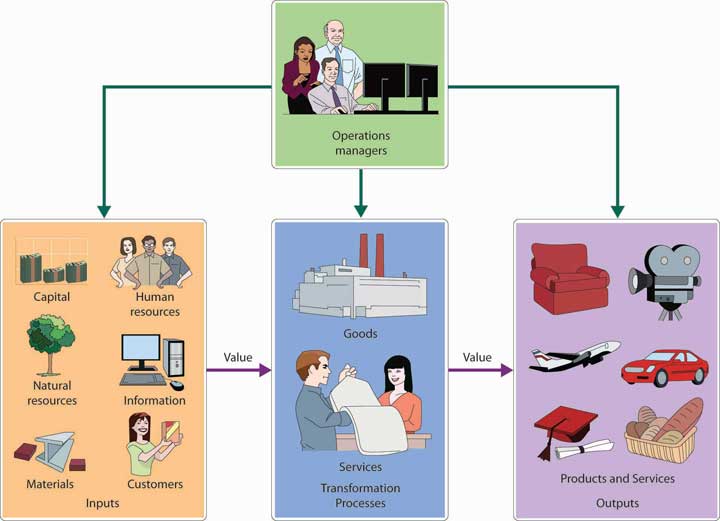

Like PowerSki, every organization—whether information technology produces goods or provides services—sees Job 1 equally furnishing customers with quality products. Thus, to compete with other organizations, a company must convert resource (materials, labor, money, information) into goods or services as efficiently equally possible. The upper-level director who directs this transformation procedure is called an operations manager. The chore of operations direction (OM), then, consists of all the activities involved in transforming a product idea into a finished product, also as those involved in planning and controlling the systems that produce goods and services. In other words, operations managers manage the procedure that transforms inputs into outputs. Effigy 11.1 "The Transformation Process" illustrates this traditional office of operations management.

Effigy 11.ane The Transformation Process

In the rest of this affiliate, we'll discuss the major activities of operations managers. Nosotros'll start by describing the role that operations managers play in the various processes designed to produce goods and offer services. Next, we'll look at the production of goods in manufacturing firms; and so, we'll draw operations management activities in companies that provide services. We'll wrap up the chapter past explaining the function of operations management in such processes every bit quality control and outsourcing.

Operations Management in Manufacturing

Like PowerSki, all manufacturers set up out to perform the same basic function: to transform resources into finished goods. To perform this office in today's business environment, manufacturers must continually strive to better operational efficiency. They must fine-tune their production processes to focus on quality, to hold downward the costs of materials and labor, and to eliminate all costs that add no value to the finished production. Making the decisions involved in the effort to attain these goals is the job of the operations managing director. That person's responsibilities can be grouped as follows:

- Product planning. During production planning, managers determine how goods will be produced, where production volition accept place, and how manufacturing facilities will be laid out.

- Product command. In one case the production process is nether manner, managers must continually schedule and monitor the activities that make up that process. They must solicit and answer to feedback and brand adjustments where needed. At this stage, they besides oversee the purchasing of raw materials and the handling of inventories.

- Quality control. Finally, the operations manager is straight involved in efforts to ensure that goods are produced according to specifications and that quality standards are maintained.

Let'southward take a closer await at each of these responsibilities.

Planning the Production Process

The decisions made in the planning stage have long-range implications and are crucial to a firm'due south success. Before making decisions about the operations process, managers must consider the goals set past marketing managers. Does the company intend to be a low-cost producer and to compete on the basis of price? Or does it plan to focus on quality and go afterwards the high end of the market? Perhaps it wants to build a reputation for reliability. What if information technology intends to offer a broad range of products? To make things fifty-fifty more complicated, all these decisions involve merchandise-offs. Upholding a reputation for reliability isn't necessarily compatible with offering a wide range of products. Low cost doesn't usually go hand in hand with loftier quality.

With these factors in mind, let's await at the specific types of decisions that have to be made in the production planning process. We've divided these decisions into those dealing with production methods, site pick, facility layout, and components and materials management.

Production-Method Decisions

The first footstep in production planning is deciding which type of production process is best for making the goods that your visitor intends to manufacture. In reaching this determination, you should reply such questions as the following:

- How much input do I receive from a particular customer before producing my appurtenances?

- Am I making a i-of-a-kind good based solely on customer specifications, or am I producing loftier-volume standardized goods to exist sold later on?

- Do I offer customers the option of "customizing" an otherwise standardized expert to meet their specific needs?

One way to capeesh the nature of this decision is past comparison three basic types of processes or methods: make-to-order, mass production, and mass customization. The task of the operations managing director is to piece of work with other managers, particularly marketers, to select the process that best serves the needs of the company'due south customers.

Make-to-Lodge

At in one case, most consumer goods, such equally article of furniture and clothing, were fabricated by individuals practicing diverse crafts. By their very nature, products were customized to see the needs of the buyers who ordered them. This procedure, which is called a make-to-lodge strategy, is withal normally used by such businesses as print or sign shops that produce low-volume, loftier-variety goods according to client specifications.

Mass Production

Effigy xi.ii

Automakers produce a high volume of cars in anticipation of futurity demand.

By the early twentieth century, all the same, a new concept of producing appurtenances had been introduced: mass production (or make-to-stock strategy) is the practice of producing high volumes of identical goods at a toll low enough to toll them for large numbers of customers. Goods are made in anticipation of hereafter demand (based on forecasts) and kept in inventory for later sale. This arroyo is especially appropriate for standardized goods ranging from processed foods to electronic appliances.

Mass Customization

Only in that location's a disadvantage to mass production: customers, every bit one gimmicky advertizement slogan puts it, can't "have it their manner." They have to accept standardized products as they come up off assembly lines. Increasingly, however, customers are looking for products that are designed to arrange individual tastes or needs but can still be bought at reasonable prices. To meet the demands of these consumers, many companies have turned to an approach called mass customization, which (as the term suggests) combines the advantages of customized products with those of mass production.

This arroyo requires that a visitor collaborate with the customer to observe out exactly what the customer wants and and so manufacture the skillful, using efficient production methods to hold down costs. One efficient method is to mass-produce a product up to a sure cut-off point and then to customize it to satisfy different customers.

The list of companies devoting at least a portion of their operations to mass customization is growing steadily. One of the best-known mass customizer is Nike, which has accomplished success by allowing customers to configure their own able-bodied shoes, apparel, and equipment through Nike's iD plan. The Web has a lot to do with the growth of mass customization. Levi's, for example, lets a woman notice a pair of perfect plumbing fixtures jeans by going through an online plumbing fixtures process that first identifies her "curve" type: slight (directly effigy), demi (evenly proportioned), bold (curvy figure, which experiences waist gapping in the dorsum), and supreme (curviest shape, which needs a higher rise in the dorsum). Oakley offers customized sunglasses, goggles, watches, and backpacks, while Mars, Inc. can make M&M'south in whatsoever color the customer wants (say, school colors) equally well as add text and pictures to the candy1.

Naturally, mass customization doesn't work for all types of goods. Well-nigh people don't care about customized detergents or paper products (although a customized Kleenex tissue box with your picture on it and a statement that says, "go ahead…weep over me!" might come in handy after a relationship breakup with your pregnant other (Windisman, 2008).) And while many of u.s.a. like the idea of customized clothes, footwear, or sunglasses from Levi's, Nike, or Oakley, we oft aren't willing to pay the higher prices they command.

Facilities Decisions

After selecting the best production process, operations managers must then decide where the goods will be manufactured, how large the manufacturing facilities will be, and how those facilities will be laid out.

Site Selection

In choosing a location, managers must consider several factors:

- To minimize shipping costs, both for raw materials coming into the establish and for finished appurtenances going out, managers often desire to locate plants close to suppliers, customers, or both.

- They generally want to locate in areas with ample numbers of skilled workers.

- They naturally adopt locations where they and their families will bask living.

- They want locations where costs for resources and other expenses—state, labor, construction, utilities, and taxes—are low.

- They look for locations with a favorable business concern climate—ane in which, for example, local governments might offer financial incentives (such as tax breaks) to entice them to practise business concern in their locales.

Managers rarely find locations that run into all these criteria. Equally a rule, they place the virtually important criteria and aim at satisfying them. In deciding to locate in San Clemente, California, for instance, PowerSki was able to satisfy iii important criteria: (1) proximity to the firm'due south suppliers, (ii) availability of skilled engineers and technicians, and (3) favorable living atmospheric condition. These factors were more of import than operating in a depression-cost region or getting fiscal incentives from local authorities. Considering PowerSki distributes its products throughout the globe, proximity to customers was besides unimportant.

Capacity Planning

Now that you know where you lot're going to locate, yous have to determine on the quantity of products that you'll produce. You brainstorm past forecasting demand for your product. Equally we discussed in Chapter 10 "Product Design and Development", forecasting isn't easy. To gauge the number of units that you're probable to sell over a given menses, you take to understand the manufacture that you're in and estimate your likely share of the market by reviewing manufacture data and conducting other forms of research.

In one case you've forecasted the demand for your product, y'all tin can calculate the chapters requirements of your production facility—the maximum number of goods that it tin can produce over a given fourth dimension under normal working conditions. In turn, having calculated your chapters requirements, you're gear up to determine how much investment in plant and equipment yous'll take to make, too equally the number of labor hours required for the plant to produce at capacity.

Like forecasting, chapters planning is difficult. Unfortunately, failing to residuum capacity and projected need can exist seriously detrimental to your bottom line. If you fix capacity likewise low (and then produce less than you should), you won't be able to meet demand, and you'll lose sales and customers. If you lot set capacity too high (and turn out more units than you should), y'all'll waste resources and inflate operating costs.

Key Takeaways

- The job of operations direction is to oversee the process of transforming resource into goods and services.

- The role of operations managers in the manufacturing sector includes production planning, production control, and quality control.

- During product planning, managers decide how goods will be produced (product process), where production volition take place (site selection), and how manufacturing facilities will be laid out (layout planning).

- In selecting the appropriate production process, managers compare three bones methods: make-to-order strategy (goods are made to customer specifications), mass production or make-to-stock strategy (loftier volumes of goods are made and held in inventory for later on sale), and mass customization (high volumes of customized goods are made).

- In choosing the site for a company's manufacturing operations, managers await for locations that minimize shipping costs, take an aplenty supply of skilled workers, provide a favorable community for workers and their families, offer resource at low toll, and take a favorable business organization climate.

- Managers estimate the quantity of products to be produced by forecasting demand for their product and then calculating the capacity requirements of the product facility—the maximum number of goods that it tin can produce over a given period under normal working conditions.

Exercises

-

(AACSB) Analysis

2 old surfers invented a textile for surfboards that's lighter and stronger than annihilation manufacturers at present use. They accept received funding to gear up up a production facility, and they want you to help them select a location. In addition to your recommendation, identify the factors that you considered in reaching your determination.

-

(AACSB) Analysis

Compare and dissimilarity three common types of product processes: brand-to-order, make-to-stock, and mass customization. What are the advantages and disadvantages of each? Why are more companies devoting at least a portion of their operations to mass customization? Identify three goods that could probably be adjusted to mass customization and iii that probably couldn't.

oneSee these websites for examples of customized products: Nike (http://nikeid.nike.com/nikeid/index.jsp), Levi (http://u.s..levi.com/shop/alphabetize.jsp?categoryId=4370093), Oakley (http://www.oakley.com/custom), and Mar's K&M'southward (http://www.mymms.com/utility.aspx?src=) (accessed November 2, 2011).

References

Windisman, A., "Personalized Packaging: Kleenex Offers Customizable Tissue Boxes," 1 of a Kind Publishing, Inc., January 3, 2008, http://blogs.oneofakindpublishing.com/index.php?/archives/77-Personalized-Packaging-Kleenex-Offers Customizable-Tissue-Boxes.html (accessed November 1, 2011).

Source: https://open.lib.umn.edu/exploringbusiness/chapter/11-1-operations-management-in-manufacturing/

Posted by: bratcherwithile1984.blogspot.com

0 Response to "How Does Southwestã¢â‚¬â„¢s Customer Service Affect Its Bottom Line"

Post a Comment